RayScan +

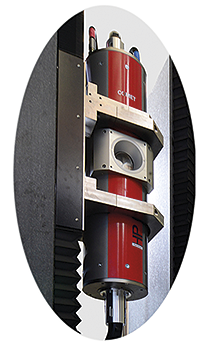

Configurable 3D CT System that can be simultaneously equipped with various X-ray sources and various X-ray detectorsBrilliant micro-focus sources in combination with flat panel detectors enable high-resolution 3D micro-CT.

Alternatively, the combination of a powerful X-ray tube and a linear detector array allows high contrast imaging of particularly large or massive objects.

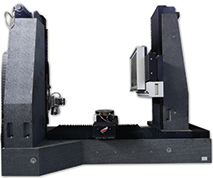

The basis for RayScan+ is the modular RayScan manipulator system made of high-precision granite, customizable automated axes, as well as guides and bearings for highest accuracy and loads.

Operating and monitoring of all hardware and software components is performed using RayWare® software package. All functions are accessible in a comprehensive and intuitive user interface.

Whether classic non-destructive testing, dimensional measurement or reverse engineering - the applications for RayScan+ are versatile – the possibilities nearly unlimited.

Technical Data

| X-ray source | Microfocus | Minifocus | ||

| High voltage | 10 - 300 kV | 50 - 600 kV | ||

| Focal spot size | from < 1 μm | from 0.25 mm |

| X-ray detectors | Flat panel | LDA | ||

| Pixels | 1000² - 4000² | 1000 - 4000 | ||

| Pixel pitch | 100 - 400 µm | 200 - 400 µm | ||

| Dynamics | 14 - 16 Bit | 16 Bit |

| Manipulator | |

| Number of axes | up to 8 |

| Accuracy | < 5 µm |

| Scanning area (horizontal) | < 1000 mm |

| Scanning area (vertical) | <2000 mm |

| Test objects | ||

| Max. Weight | 300 (opt. 500) kg | |

| Dimensions | < 1 mm - > 5 m | |

| Materials | Light metals, Ceramics, Plastics, Composites |

| Scanning methods |

| 2D-CT, 3D-CT, ROI-CT, Transversal CT, Helical-CT, Radioscopy |

| Modularity |

| Dimensions and choice of components will be customised |